Machines

- UBM Vertical Type Cold Roll Forming Machine

- ACM No-Girder Arch Roof Forming Machine

- SX-ACM-1000-750 - SX-ACM-1000-700 - SX-ACM-1000-680 - SX-ACM-1000-630 - SX-ACM-1000-800 - SX-ACM-1200-800 - SX-ACM-1250-800 - SX-ACM-1250-500 - SX-ACM-1220-800 - SX-ACM-1000-610 - SX-ACM-1000-550 - SX-ACM-914-400 - SX-ACM-625-330 - SX-ACM-600-305 - SX-ACM-500-205 - SX-ACM-914-610 - SX-ACM-914-650 - SX-ACM-1000-400 - SX-ACM-914-750 - SX-ACM-914-700 - SX-ACM-300-178

- No-Girder Nut&Bolt Multiple Shape Building Produci

- KR Standing Seam Roof Forming Machine

- Military Large Span Beamless Building Machinery

- Screw-joint No-Girder Large Span Roof Making Machi

- No-girder Small Span Building Machine

- Double-groove No-girder Screw-Joint Multiple Shape

- Spiral Seaming Type Steel Silo Machine

- Standing Seam Dome Roofing Fan-shaped Panel Machin

- Gutter and Irregular Machine

- Flat Sheet Corrugated Roll Forming Machine

- Glazed Tile Corrugated Roll Forming Machine

- Sandwich Panel Producing Line

- Automatic Stacker

- Deck Floor Roll Forming Machine

- Automatic Slitting Line

- Rolling Door Producing Line

- Guard Rail Forming Machine

- U/C/Z Shape Steel Purlin Machine

- Light Steel-Frame Structure Production Line

- Hydraulic Shearing Machine

- Hydraulic Bending Machine

- Automatic Lifting Platform

- Gable Wall Bending Machine

- High Pressure Polyurethane Insulation Machine

- Multiple Function Painting Car

- Sx-50 steel coil transporter

- Sanxing SP Painting production line

- Sanxing SP Painting

- Steel and Aluminum Coil

- FRP Skylight Panel

- Aluminum Alloy Bracket

- Wind Cap

- Automatic Tube Bending Machine

- SP stone painting

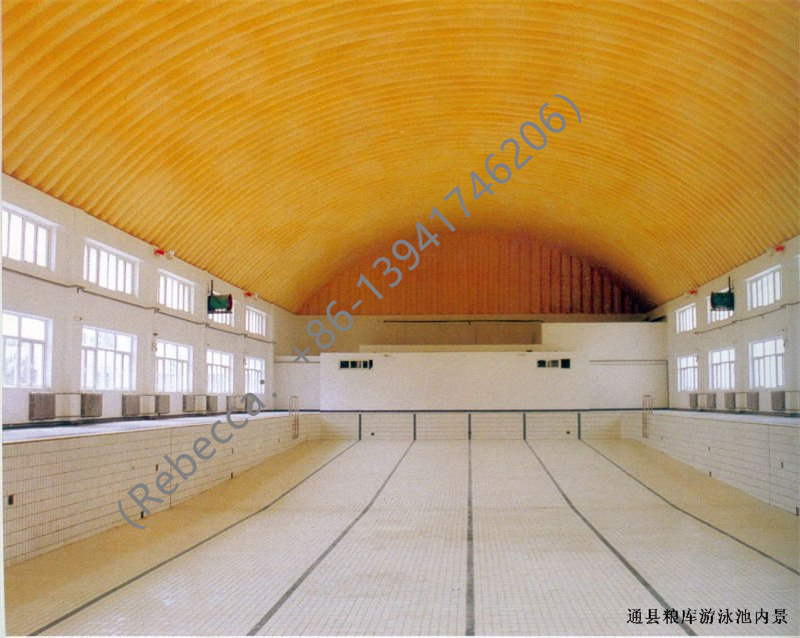

- Quonset Huts

High Pressure Polyurethane Insulation Machine

| Add: | No.69 Hailan Street, Yingkou Area of China (Liaoning) Pilot Free Trade Zone |

|---|---|

| Tel: | +86-417-2604444 |

| Mobile/Whatsapp/Wechat: | +86-13941746206 |

| Email: | rebecca@yksanxing.com |

|

产品介绍

The performance parameters of the system cover the same kind of traditional two-component spraying equipment, so it can meet the application requirements in the same two-component spraying application field, at the same time, it has a wider use and promotion space in the application fields of timing, quantitative, accurate control, assembly line spraying production and so on.

Sanxing polyurethane high pressure airless spraying (pouring) molding system, adopts machining center parts to ensure the mixing pressure required for two-component raw materials.;2500 w of independent heaters to provide reliable heating source for raw materials, thus effectively solve the viscosity problem of raw materials ;15 meters of heating insulation line to ensure that the heat of heated raw materials do not lose; no solvent spray gun cleaning system, make your operation, maintenance easier.

Standard configuration

Host :1

Spray gun :1

Heating insulation line :15 m

Combined short barrel: 1 set of 3 m

Feed pump : 2

Tools :1 set

Operation Manual :1 set

Technical parameters

Raw material ratio: 1:1

Raw material viscosity range: 200 ~ 1000CPS

Raw material output: 4-8kg/ min

Heating power of raw material: 2500W×2

Heating power of pipeline: 2000W

Electrical source: single phase 220V 7000W 50Hz

Air source: 0.5-0.8mpa (70~120psi) ≥0.9m3/min

Output pressure of single component raw material: 5-10mpa

Maximum length of pipeline: 45 meters